Even high-quality WPC decking can fail if installed the wrong way. So, what are the most common mistakes people make when laying WPC deck flooring, and how can we avoid them?

The 17 common mistakes in installing WPC deck flooring include issues with base preparation, gaps, fixings, ventilation, alignment, and expansion control—each affecting durability and appearance.

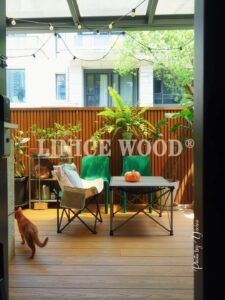

When I first used WPC decking on a patio, I underestimated how sensitive it was to proper spacing and drainage.

A few months later, some boards swelled at the edges. That taught me that precise installation is as important as the product itself.

Let’s walk through each point that helps you avoid costly or time-wasting errors.

Why do common mistakes happen in WPC decking installation?

WPC decking seems simple to fit—just boards and screws—but it’s a composite material with specific behavior.

Most mistakes happen because people treat WPC like natural wood, ignoring its need for expansion, support, and ventilation.

I made that mistake once—assuming I could fix boards tightly like wood planks. The expansion caused bulges soon after the weather changed.

WPC expands and contracts slightly with temperature, so you have to leave small gaps for it to move freely. Proper understanding of the material solves many headaches.

| Cause | Description | Preventive Action |

|---|---|---|

| Wrong Assumptions | Treating WPC like timber. | Follow composite installation guides. |

| Improper Tools | Using standard wood equipment. | Use proper clips and composite screws. |

| Neglected Base Work | Uneven foundations or poor drainage. | Level and waterproof the subfloor first. |

Small preparation errors can grow into big repairs if not managed early.

What are the 17 most common mistakes when installing WPC deck flooring?

Detailed planning matters before you fix a single board. Let’s look at each problem and the solution.

Here are the 17 most common installation mistakes:

I’ve seen most of these during site inspections—each correctable when you know what to avoid.

| No. | Mistake | Description | What It Leads To | Recommended Fix |

|---|---|---|---|---|

| 1 | Uneven Ground | Laying boards on rough soil or tiles. | Boards sit unevenly and break under pressure. | Create a level, solid substructure. |

| 2 | No Drainage Slope | Deck surface traps rainwater. | Water pooling causes mold and board warping. | Leave 1–2% slope for water runoff. |

| 3 | Tight Board Spacing | No room for expansion. | Boards buckle or lift in hot weather. | Leave 5–7 mm gaps between boards. |

| 4 | No Edge Clearance | Boards press against walls. | Edges crack from thermal movement. | Keep at least 10 mm gap from walls. |

| 5 | Wrong Joist Distance | Weak support spacing. | Deck flexes or collapses under weight. | Follow supplier’s recommended span (usually 300–400 mm). |

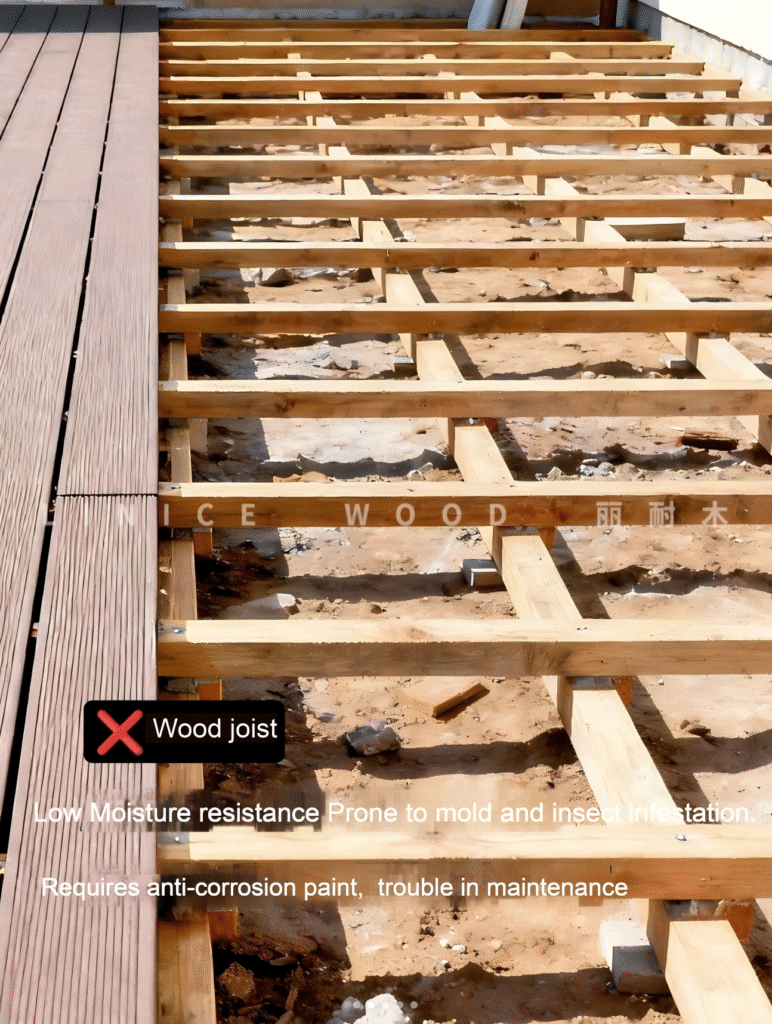

| 6 | Mixing Materials | Using wood joists below composite boards. | Wood rots or expands unevenly. | Use compatible composite or aluminum joists. |

| 7 | Ignoring Airflow | No ventilation under deck. | Moisture builds up, causing mold and odor. | Leave 50 mm space under deck for airflow. |

| 8 | Fixing Too Tight | Screws or clips over-tightened. | Limits movement, leading to crack lines. | Fasten firmly but don’t restrict board movement. |

| 9 | Random Joint Alignment | Boards staggered unevenly. | Deck looks messy and lacks strength. | Align joints or plan stagger pattern. |

| 10 | Missing Expansion Joins | Large decks installed in one piece. | Whole surface warps from uniform expansion. | Add expansion gaps every 5–6 meters. |

| 11 | Wrong Screw Type | Standard steel screws rust easily. | Screws stain and weaken deck integrity. | Use stainless or composite-grade fasteners. |

| 12 | Not Sealing Ends | Unsealed cuts absorb moisture. | Ends swell, discolor, or crack. | Apply end caps or waterproof sealant. |

| 13 | Poor Frame Anchoring | Joists not fixed securely to base. | Deck feels loose and unstable. | Anchor framing with corrosion-resistant brackets. |

| 14 | Installing in Extreme Heat | Boards installed when expanded. | Boards shrink later and cause gaps. | Install in mild temperature for stable fit. |

| 15 | Skipping Subfloor Inspection | Old floors left unstable. | Deck may sink or shift over time. | Inspect subfloor for cracks or softness. |

| 16 | No Cleaning During Fixing | Dust left between clips or joins. | Improper lock and uneven joint surfaces. | Clean all debris while installing. |

| 17 | Not Reading Manufacturer Manual | Ignoring specification details. | Incorrect installation voids warranty. | Follow brand-specific instructions carefully. |

Each issue may seem small, but even one can compromise the entire deck’s integrity or look.

How can I ensure a perfect WPC deck installation?

Avoiding mistakes starts with careful planning and respect for the material’s nature.

To install WPC decking correctly, always follow manufacturer spacing guides, use a stable base with proper drainage, and allow airflow beneath the boards.

I often prepare a simple checklist before installing. It usually includes checking alignment, fastening type, and ventilation clearance.

I also confirm the material temperature before cutting so lengths remain accurate later.

For large projects, pre-assembling a few boards helps spot early fitting problems before committing to full installation.

| Step | Detail | Benefit |

|---|---|---|

| Prepare Base | Level, dry, and solid foundation. | Prevents cracks or movement. |

| Space Right | Leave temperature gaps at board ends. | Avoids bulges or warping. |

| Secure Properly | Use matched clips and screws. | Maintains board stability. |

| Finish Ends | Cap or seal cut surfaces. | Protects against moisture. |

| Clean Up | Remove dirt during fitting. | Prevents improper joint alignment. |

By being precise, the finished deck not only looks better but also lasts much longer without repairs.

Why is professional installation or guidance recommended?

Even with easy-to-handle boards, WPC decking benefits from professional guidance—especially for commercial or coastal areas.

A skilled installer understands structure, slope, and drainage, reducing risks of long-term damage or costly redo.

In one beachfront cafe project, the owners started the installation themselves. Within six months, uneven slope caused water pooling, leading to quick color variation. After professional correction, the deck has now lasted years without issue.

Expertise doesn’t just add precision—it protects your investment. If full installation services aren’t available, most good manufacturers, like LiNice Wood, can provide technical guides or video assistance.

| Area | DIY Risk | Professional Benefit |

|---|---|---|

| Leveling | May stay uneven. | Correct slope ensures drainage. |

| Fastening | Overtight or loose clips. | Balanced tension for durability. |

| Expansion Gaps | Often ignored. | Proper spacing prevents swelling. |

| Overall Finish | Visible gaps or misalignment. | Cleaner appearance and stronger bond. |

Guided installation makes your WPC decking function as intended, with fewer worries post-installation.

Conclusion

Most WPC deck failures come from small installation mistakes, not poor materials. Follow spacing, slope, and airflow rules carefully to build a beautiful, long-lasting deck floor.

Linice Wood – The Leading WPC Deck Flooring Manufacturer in China

Linice Wood is the leading WPC deck flooring manufacturer in China, leveraging over 12 years of innovation in wood-plastic composite technology.

Our eco-friendly, slip-resistant decking delivers exceptional durability and low maintenance for both residential and commercial landscapes.

Equipped with state-of-the-art production lines and stringent quality controls, Linice Wood ensures consistency and superior performance across all projects.

Partner with us for bespoke color options, efficient lead times, and competitive pricing today!