The global demand for composite decking is growing rapidly. Homeowners, landscapers, and commercial developers are looking for durable, low-maintenance, and visually appealing decking solutions. Many importers see China as the go-to source for high-quality, cost-effective composite decking thanks to its mature manufacturing industry.

However, importing from China isn’t always straightforward. Challenges include:

- Finding reliable suppliers among thousands of options

- Understanding different decking types, finishes, and accessories

- Calculating the total costs including shipping, duties, and installation components

- Avoiding quality issues, delays, or hidden fees

Without proper guidance, first-time importers risk wasted time, money, and effort.

This guide walks you through the entire import process step by step. From selecting the right type of decking and researching the market $8-$13to finding reliable suppliers, confirming specifications, and choosing the best shipping solution — you’ll gain the confidence to import composite decking efficiently and profitably.

By following these chapters, you’ll know exactly how to:

- Choose the right decking type for your market

- Verify supplier credibility and capacity

- Get accurate quotes and negotiate favorable terms

- Ensure safe, cost-effective shipping

- Build a reliable long-term supplier relationship

Start your journey to importing composite decking from China with clarity, confidence, and control.

Chapter 1. How Much USD Budget You May Need

Before importing composite decking from China, it’s important to know your total budget. Your costs will include the decking itself, shipping, customs fees, and delivery to your warehouse.

Here’s a simple breakdown to help you plan — whether you’re starting small with one pallet or going for a full container.

Composite decking prices depend on material and surface type.

Below are common factory price ranges in China:

1. Product Cost

| Type | Description | Price (USD/m²) | Price (USD/ft²) |

|---|---|---|---|

| Hollow Decking | Lightweight and cost-effective | $11 – $15 | ≈ $1.02 – $1.39 |

| Solid Decking | Stronger and denser for higher durability | $17 – $26 | ≈ $1.58 – $2.42 |

| Co-extruded (Capped) Decking | Premium surface with enhanced protection | $15 – $25 | ≈ $1.39 – $2.32 |

Note: 1 m² ≈ 10.76 ft². Prices per ft² are approximate conversions for easy reference.

Prices are for reference only and may vary depending on order quantity, specification, and market conditions.

💡 Tip: Co-extruded decking offers better color stability and longer life, ideal for outdoor projects or high-end markets.

2. Order Quantity Options

You can import 1 pallet (small test order) or 1 full container (bulk order).

Let’s see how the cost differs.

Example A — Importing 1 Pallet

| Item | Details | Estimated Cost (USD) |

|---|---|---|

| Product Value | 100 m² × $15/m²( 1,076.4 ft² × $1.39/ft²) | $1,500 |

| Sea Freight (LCL) | Shared container | $300–$500 |

| Destination Fees + Customs | Clearance, duty, tax | $200–$400 |

| Inland Delivery (Optional) | To your warehouse | $100–$200 |

| Total Estimated Cost | $2,000–$2,500 |

🟢 Best for small businesses testing the market or sample installations.

🟢 Expect a total landed cost around $20–$25 per m², including shipping.

Example B — Importing 1 Full Container (40ft HQ)

| Item | Details | Estimated Cost (USD) |

|---|---|---|

| Product Value | 2,000 m² × $15/m²( 21,527.8 ft² × $1.39/ft²) | $30,000 |

| Sea Freight (FCL) | Full 40ft HQ | $1,200–$1,800 |

| Customs + Duty + VAT | Around 8–12% | $3,000–$4,000 |

| Inland Delivery | From port to warehouse | $400–$800 |

| Total Estimated Cost | $35,000–$37,000 |

🟢 Best for distributors, wholesalers, or ongoing projects.

🟢 The average landed cost drops to $17–$19 per m² — much more cost-efficient than buying one pallet.

3. Other Costs to Consider

| Cost Item | Description | Estimated Range |

|---|---|---|

| Sample & Testing Fee | For pre-shipment quality check | $100–$200 |

| Packaging / Pallet Fee | Usually included, or $25–$30/pallet | $25–$30 each |

| Insurance | Optional, covers loss or damage | 0.3–0.5% of cargo value |

| Bank Transfer Fee | For international payment | $30–$50 per transaction |

💡 Tip: Always confirm whether the supplier’s quote includes pallets, export packing, and port charges (EXW vs. FOB vs. CIF makes a big difference).

4. Budget Summary

| Import Scale | Estimated Total Budget | Average Landed Cost per m² | Recommended For |

|---|---|---|---|

| 1 Pallet | $2,000–$2,500 | $20–$25 | Small test or sample project |

| 1 Container (40ft HQ) | $35,000–$37,000 | $17–$19 | Wholesalers / Distributors |

5. Smart Planning Tips

- Always compare quotes from 2–3 suppliers before confirming.

- Ask for CIF or DDP pricing to understand your full landed cost.

- Plan your order to fill one container — shipping efficiency improves dramatically.

- Keep 10–15% buffer in your budget for taxes or exchange rate changes.

In Summary

Your total budget depends on order size.

A one-pallet test order helps you verify product quality and supplier reliability with around $2,000–$2,500.

Once confirmed, a full container shipment offers much better value at roughly $17–$19 per m², ideal for bulk sales or long-term projects.

Careful budgeting from the start ensures a smooth and profitable import experience.

Chapter 2. What Composite Decking Types to Import from China?

When importing composite decking from China, you’ll find a wide range of options designed for different applications, aesthetics, and budgets. Understanding the main types helps you choose the right product for your market and customers.

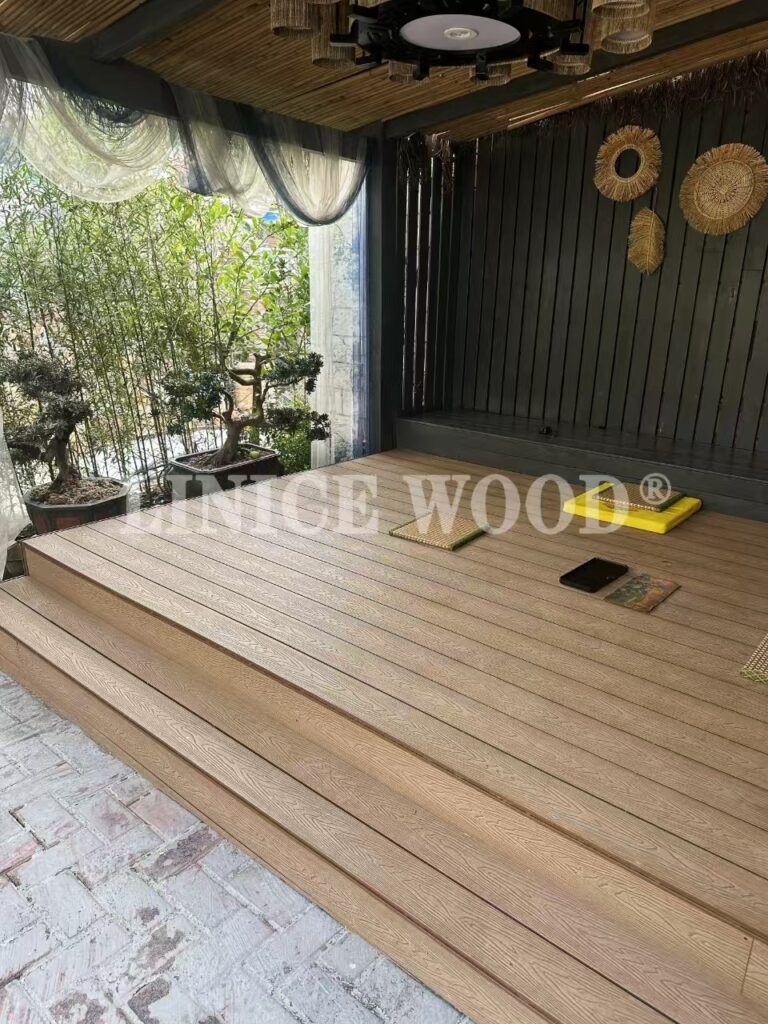

1. Hollow vs. Solid Decking

Hollow Decking

- Lightweight and more affordable

- Easier to handle and install

- Suitable for residential or low-traffic areas

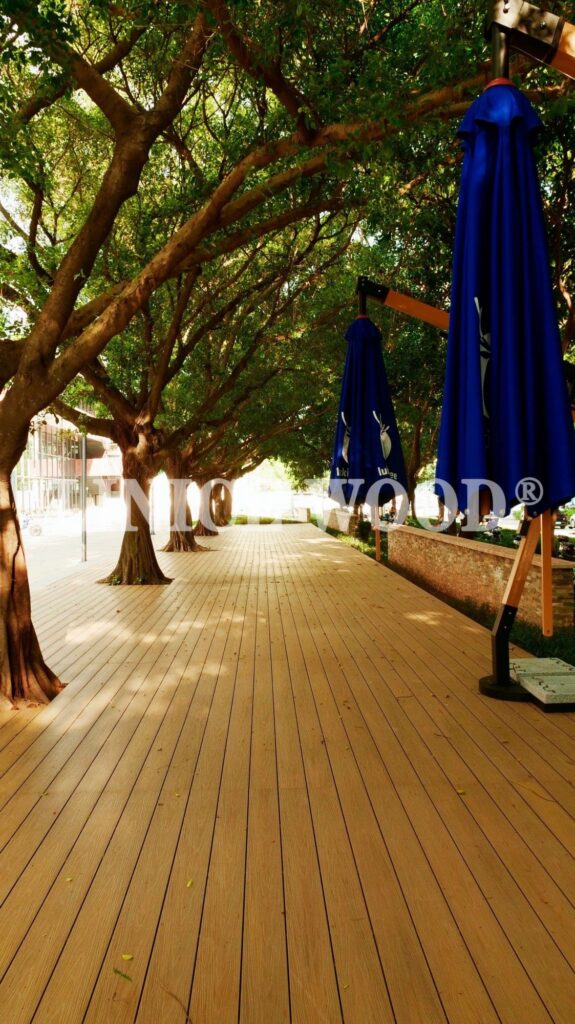

Solid Decking

- Heavier and stronger

- Withstands high foot traffic and harsh weather

- Ideal for commercial projects, boardwalks, and public spaces

💡 Tip: Solid decking is more popular in colder climates, while hollow boards are preferred for cost-sensitive markets.

2. Capped vs. Uncapped Decking

Capped Composite Decking

- Protected by a polymer shell layer

- More resistant to fading, staining, and moisture

- Premium look and longer lifespan

Uncapped Decking

- Pure WPC material (wood-plastic composite)

- Lower cost but needs more maintenance

- Best for short-term or budget projects

💡 Tip: If your market values low maintenance, go for capped decking.

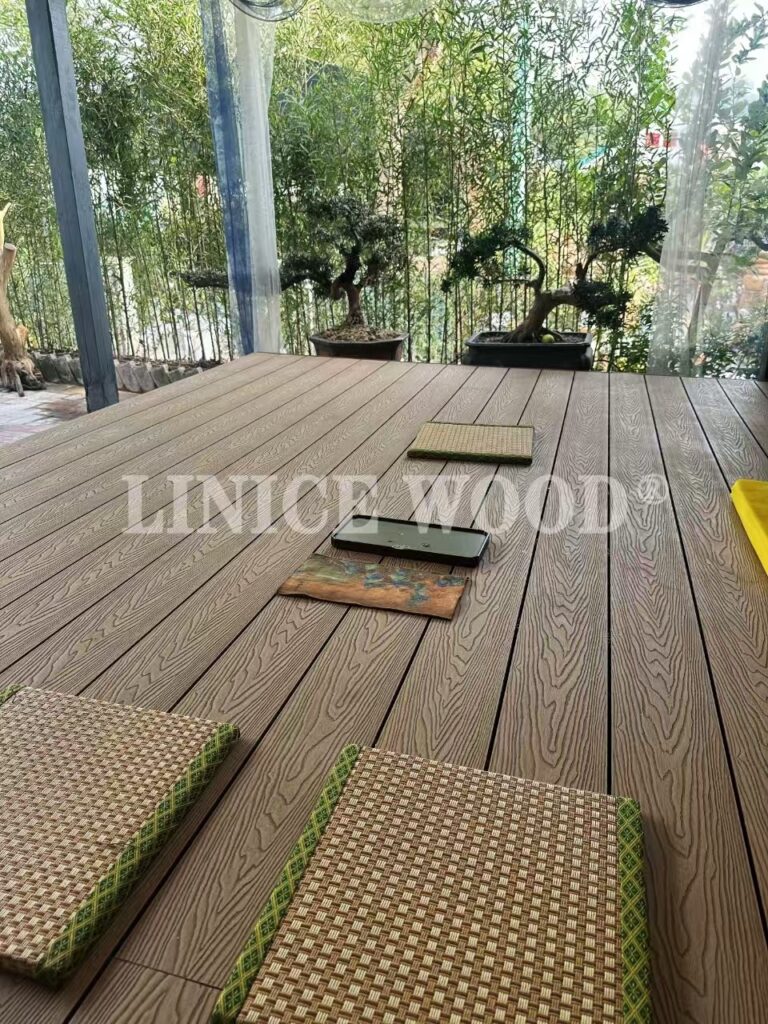

3. Surface Textures & Finishes

Chinese factories can produce various surface designs:

- Wood Grain – Imitates real timber texture

- Sanding Finish – Smooth and elegant feel

- Brushed Finish – Anti-slip, modern appearance

- 3D Embossed – Deep grain texture, premium visual effect

💡 Tip: 3D embossed decking is currently trending in Europe and North America.

4. Decking Accessories to Consider

When importing, don’t forget matching accessories:

- Joists and edge trims

- Clips and screws (stainless steel or plastic)

- Fascia boards and stair nosings

- Color-matched end caps

These small items complete your system and help your customers with installation.

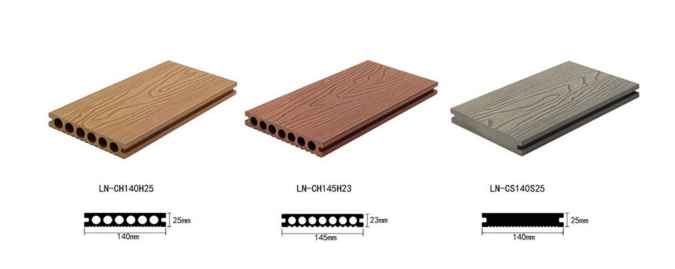

5. Standard Sizes & Profiles

Most factories offer:

- Width: 140mm–150mm

- Thickness: 20mm–25mm

- Length: 2.2m–5.4m (customizable)

Common profiles:

- Grooved edge for hidden clip installation

- Square edge for face screw fixing

6. Customization Options

Chinese suppliers allow flexible customization:

- Color (teak, gray, coffee, black, etc.)

- Embossing pattern

- Surface finish

- Branding or private label packaging

💡 Tip: You can start with factory standard colors first, then add custom tones once your sales grow.

Summary

| Type | Advantage | Recommended Use |

|---|---|---|

| Hollow | Light, affordable | Home backyard, small decks |

| Solid | Strong, durable | Commercial, high-traffic |

| Capped | Low maintenance | Premium market |

| Uncapped | Cost-effective | Entry-level market |

Chapter 3. How to Do Product Research Before Importing from China

Before you place your first order, you need to understand what type of composite decking sells well in your target market. Doing good product research helps you avoid slow-moving inventory and find products that fit your customer’s needs.

1. Study Your Local Market

Start by learning what’s already popular in your country.

You can:

- Visit home improvement stores like Home Depot, B&Q, or Lowe’s to see decking colors, sizes, and prices.

- Check local builders or landscapers’ portfolios to know which styles are trending.

- Observe project photos on Pinterest or Instagram — they reflect consumer taste quickly.

💡 Tip: Take note of the surface finish, color tone, and installation system used most often.

2. Compare Price Ranges

Composite decking prices vary depending on the material and cap layer:

| Decking Type | Factory Price (China) | Retail Price (Your Market) | Profit Potential |

|---|---|---|---|

| Hollow WPC | $9–$13/m² | $35–$50/m² | Medium |

| Solid WPC | $13–$18/m² | $45–$65/m² | High |

| Capped WPC | $16–$22/m² | $55–$80/m² | Very High |

By comparing factory vs. retail prices, you can estimate your profit margin and find the most profitable type for import.

3. Check Application Demand

Different markets prefer different decking types:

- Europe: Capped, wood grain, anti-slip, deep embossed finish.

- Australia: Solid decking with UV-resistant colors.

- USA: Environment-friendly WPC with hidden fasteners.

- Middle East: Hollow decking, lighter colors for heat reflection.

💡 Tip: Match your product choice with local climate and design trends.

4. Research Installation Systems

Ask yourself:

- Do your customers prefer hidden clips or screwed-down systems?

- Are installers familiar with composite joists or wood subframes?

- Do local regulations require fire or slip resistance certificates?

Understanding this early saves you from importing products that can’t be easily installed or approved locally.

5. Use Online Tools for Market Insights

You can get fast data from:

- Google Trends – to see keyword popularity (e.g., “composite decking gray” or “capped decking”).

- Alibaba & Made-in-China – to compare supplier prices and specifications.

- Amazon / Wayfair / eBay – to check what styles get the best reviews.

- Facebook Marketplace & Houzz – to study how sellers promote and price similar products.

💡 Tip: Look for customer reviews — they often reveal what problems to avoid (e.g., color fading, expansion, or scratching).

6. Test the Market First

Instead of ordering a full container right away, try:

- Importing 1–2 pallets for trial sales.

- Showing samples to local contractors or distributors.

- Using feedback to fine-tune your main order (color, surface, length, etc.).

Starting small reduces risk and helps you build the right product mix.

Summary

Before importing composite decking, research these 5 key areas:

- Local demand and visual trends

- Retail price range vs. factory cost

- Preferred material type (solid/hollow, capped/uncapped)

- Installation systems

- Feedback from real users and contractors

Chapter 4. How to Find Chinese Suppliers Online

Once you identify what sells best, you can confidently move to the next step — finding reliable suppliers online.

1. Use the Right Platforms

The most direct way to find suppliers is through major B2B websites and online search engines:

| Platform / Tool | Best For | Tips |

|---|---|---|

| Alibaba.com | Largest global directory | Check “Verified Supplier” and “Manufacturer” tags |

| Made-in-China.com | Industrial and construction materials | Focus on suppliers with export experience |

| GlobalSources.com | High-end, audited suppliers | Often used by importers from Europe & US |

| 1688.com | Domestic China market (Chinese language) | Use if you have a sourcing agent |

| Google Search | Find suppliers, factories, and company websites | Use keywords like “WPC decking manufacturer China” or “capped composite decking supplier” |

💡 Tip: Google is especially useful to cross-check suppliers you find on B2B platforms and to find company websites, certifications, or reviews not listed on Alibaba or Made-in-China.

2. Identify Real Manufacturers

When reviewing supplier profiles, look for:

- Factory photos and production line videos

- ISO or CE certificates

- Registered capital (the higher, the more stable)

- Years in business (ideally 5+ years)

- Product range consistency (decking, wall cladding, fence — not mixed random items)

💡 Tip: Real decking factories often specialize in WPC extrusion, surface embossing, and co-extrusion lines.

3. Contact and Compare Suppliers

Prepare a simple inquiry message:

“Hello, I’m looking to import WPC composite decking for my market.

Please send your product catalog, MOQ, and price for 140×25mm capped decking.

Also confirm packaging details and available colors.”

Compare how suppliers respond:

- Do they answer clearly and fast?

- Do they provide complete specs, not vague answers?

- Are they professional in communication?

Fast, detailed replies usually mean solid export experience.

4. Check Product Range and Quality

Good manufacturers can offer:

- Hollow, solid, capped, and 3D embossed decking

- Accessories like joists, clips, and edge trims

- Custom branding or packaging options

- Consistent color control across batches

💡 Tip: Ask for sample kits before confirming an order. You can test surface strength, color stability, and texture.

5. Verify with Online Tools

You can use these free or low-cost tools:

- Google Maps / Street View – to check real factory locations

- ImportYeti.com – to see if the company has export records

- QCC.com (企查查) – to verify Chinese business licenses

- Alibaba Verified Reports – third-party factory audits

If the company has multiple verifications from SGS, TÜV, or BV, it’s a strong sign of legitimacy.

6. Shortlist 3–5 Suppliers

Don’t rely on just one. Create a shortlist of 3–5 potential partners and compare:

- Product quality

- MOQ (minimum order quantity)

- Price terms (FOB, EXW, CIF)

- Response speed and professionalism

Then move to the quotation and sampling stage.

Summary

To find the right decking supplier online:

- Start with trusted B2B platforms

- Identify real factories (not traders)

- Send clear inquiries and evaluate replies

- Request samples for comparison

- Use verification tools to confirm legitimacy

Once you’ve shortlisted your suppliers, you’re ready for the next phase — Chapter 5: Visiting China to Meet Suppliers in Person (optional but powerful for long-term partnerships)

.

Chapter 5. How to Find Suppliers by Visiting China

Visiting suppliers in China can give you confidence in their reliability, quality, and production capacity. While online communication and samples are useful, nothing beats seeing the factory in person.

1. Why Visit Suppliers

- Verify legitimacy – Check if the company is a real manufacturer, not just a trading company.

- Inspect production lines – See extrusion machines, surface embossing, co-extrusion lines.

- Assess quality control – Observe how they handle raw materials, finished boards, and packaging.

- Negotiate better – Face-to-face meetings often help secure better prices, MOQ, or payment terms.

💡 Tip: Even a short 1–2 day visit can reveal much more than weeks of emails.

2. Plan Your Visit

- Select a sourcing city: Shenzhen, Foshan, Shanghai, Wuxi, or Dongguan are hubs for WPC decking.

- Schedule appointments: Contact 3–5 factories before arrival.

- Prepare a checklist: Production capacity, quality control, warehouse, staff experience, export experience.

- Arrange logistics: Airport pickup, hotel near industrial areas, translator if needed.

💡 Tip: Use Google Maps to locate factories in advance and estimate travel time.

3. What to Check During the Visit

When you’re at the factory, inspect:

- Factory Facilities

- Extrusion machines, co-extrusion lines, embossing lines

- Warehouse organization and cleanliness

- Loading and packaging areas

- Quality Control Process

- Raw material storage and handling

- In-process inspection and finished product testing

- Color consistency, surface finish, and anti-slip texture

- Staff and Management

- Experience of production team

- Communication skills and willingness to answer technical questions

- Export department’s familiarity with international shipping and documentation

- Product Samples

- Compare different colors, textures, and board types

- Ask for any certifications (ISO, CE, FSC)

- Test surface strength and flexibility if possible

4. How to Evaluate Suppliers

After visiting, evaluate suppliers based on:

- Production capacity vs. your order size

- Quality and consistency of sample products

- Professionalism and communication

- Ability to provide accessories and customized orders

💡 Tip: Take photos or short videos during the visit — these help review and compare suppliers later.

5. Benefits of Visiting

| Benefit | Why It Matters |

|---|---|

| Verify legitimacy | Avoid fraud or middlemen |

| Check production capacity | Ensure they can meet your order volume |

| Assess quality control | Reduce risk of defective shipments |

| Build personal relationship | Easier negotiation and future support |

| Observe export experience | Confirm knowledge of customs, documentation, and shipping |

Summary

Visiting suppliers in China is highly recommended for importing composite decking. Even a short trip gives you clarity on:

- Factory authenticity and production capacity

- Product quality and consistency

- Staff professionalism and export readiness

Face-to-face meetings help you build trust, secure better terms, and reduce risks, making your import process smoother and safer.

Chapter 6. 8 Aspects to Help Check Chinese Suppliers

Even if visiting China isn’t possible, you can still verify suppliers carefully before placing an order. Here are 8 practical aspects to check for reliable sourcing.

1. Company Type

- Manufacturer vs. Trading Company

- Manufacturers usually offer lower prices and better quality control.

- Trading companies may have broader product range but often higher costs.

- How to check: Look for factory photos, business license, and production certifications.

2. Years in Business

- Prefer suppliers with 10+ years of experience in WPC decking.

- Longer-established suppliers are generally more stable, professional, and experienced in exporting.

3. Product Range

- Check if the supplier offers hollow, solid, capped, and 3D embossed decking.

- Accessories like joists, clips, fascia boards, and end caps indicate a complete decking system, which is easier for your customers.

4. Minimum Order Quantity (MOQ)

- Confirm the MOQ for your required type and color.

- Some factories allow mixed-color pallets or smaller trial orders.

- Knowing this helps you test the market without overspending.

5. Quality Certifications

- Ask for ISO, CE, FSC, or SGS reports.

- These documents ensure compliance with safety, durability, and environmental standards.

- Certified suppliers are often more reliable for export.

6. Production Capacity

- Confirm the supplier can handle your order size.

- Ask: How many square meters per month can they produce?

- Can they meet tight deadlines for large container orders?

7. Communication & Professionalism

- Fast and clear responses indicate good export experience.

- Ask technical questions about board thickness, surface finishes, color consistency, and installation systems.

- Suppliers who provide detailed, professional answers are more trustworthy.

8. Sample Availability

- Request sample boards before ordering.

- Compare: color, surface finish, anti-slip texture, and co-extruded quality.

- Testing samples ensures you’re importing the exact product your market demands.

Summary

Even without visiting China, you can screen suppliers using these 8 aspects:

| Aspect | Why It Matters |

|---|---|

| Company Type | Verify direct manufacturer or trading company |

| Years in Business | Stability and experience |

| Product Range | Complete decking options & accessories |

| MOQ | Flexibility for small or test orders |

| Quality Certifications | Compliance and trustworthiness |

| Production Capacity | Ability to meet your order volume |

| Communication | Professionalism and export experience |

| Sample Availability | Ensure product quality before bulk order |

By carefully checking these aspects, you reduce risks, ensure high-quality decking, and find a supplier capable of supporting your business long-term.

Chapter 7. How to Get Precise Quotes & Which Trade Terms Work Best

Once you’ve shortlisted suppliers, the next step is getting accurate quotes and understanding trade terms. This ensures you know exactly what you’ll pay and how the shipment will be handled.

1. Prepare a Clear Request for Quotation (RFQ)

A detailed RFQ helps suppliers give precise quotes. Include:

- Product type: Hollow, solid, or capped WPC decking

- Dimensions: Thickness, width, length

- Surface finish: Wood grain, brushed, or 3D embossed

- Color & quantity: Specify exact colors and total square meters

- Accessories: Clips, joists, fascia boards, end caps

- Packaging: Pallet type, boxes, labeling requirements

- Delivery port: To compare shipping costs

💡 Tip: The more details you provide, the less chance of surprises later.

2. Ask for FOB, CIF, and DDP Prices

Understanding trade terms is critical:

| Trade Term | Meaning | Pros | Cons |

|---|---|---|---|

| EXW (Ex Works) | You pick up goods at factory | Lowest factory price | You arrange export, shipping, insurance, and customs |

| FOB (Free on Board) | Supplier delivers to port of shipment | Common and flexible | You handle international shipping and import customs |

| CIF (Cost, Insurance, Freight) | Supplier ships to your port, insurance included | Easy for first-time importers | Higher cost, less control over shipping |

| DDP (Delivered Duty Paid) | Supplier delivers to your warehouse, duties paid | Very convenient, low risk | Expensive, limited suppliers can offer |

💡 Tip: For first orders or small pallets, CIF is often easiest. For large container shipments, FOB gives more flexibility and cost control.

3. Confirm Total Cost Components

A precise quote should break down:

- Product cost per m²

- Accessories cost (clips, joists, etc.)

- Packaging & pallet cost

- Shipping / freight charges

- Insurance (if CIF)

- Customs duties, VAT, or local taxes

This helps you calculate the landed cost per square meter.

4. Negotiate Smartly

- Compare 2–3 suppliers for similar products and terms.

- Ask about discounts for larger orders or long-term partnership pricing.

- Negotiate payment terms: 30% deposit + 70% balance before shipment is common, but suppliers may accept LC or other methods.

💡 Tip: Always confirm if the quote includes pallets, labeling, and port charges to avoid hidden costs.

5. Ask About Lead Time

- Confirm production lead time: usually 15–30 days for 1–2 pallets, 30–45 days for a full container.

- Ask about shipping time to your port to plan project schedules.

Summary

To get precise quotes and choose the right trade term:

- Prepare a detailed RFQ

- Request quotes with FOB, CIF, or DDP

- Confirm all cost components

- Negotiate pricing and payment terms

- Check production and shipping lead times

By following these steps, you’ll know exactly how much to budget per pallet or per container, avoid surprises, and import composite decking efficiently.

Chapter 8. How to Choose the Best Supplier (5 Checkpoints)

After shortlisting suppliers, the next step is to select the one that’s most reliable, cost-effective, and capable of supporting your business long-term. Here are 5 key checkpoints to evaluate them.

1. Product Quality

- Examine samples for consistency in color, surface finish, and size.

- Check for defects like scratches, fading, or warping.

- Ask about quality control procedures:

- Raw material inspection

- In-process checks

- Final product testing

💡 Tip: High-quality decking may cost more but saves money on returns and complaints.

2. Factory Capability

- Ensure the supplier can handle your order size:

- Pallets for small orders

- Full containers for bulk orders

- Check their production lines and machinery for:

- Hollow and solid extrusion

- Surface embossing or capping

- Ask about backup capacity in case of urgent orders.

💡 Tip: A capable factory avoids delays and keeps your supply consistent.

3. Communication & Responsiveness

- Evaluate how quickly and clearly the supplier answers your emails or calls.

- Look for suppliers who can provide:

- Technical support

- Export documentation guidance

- Shipping and logistics advice

💡 Tip: Smooth communication prevents misunderstandings and delays.

4. Certifications & Compliance

Ask for ISO, CE, FSC, SGS, or other relevant certifications.

- Confirm if the decking meets fire, slip-resistance, or environmental standards required in your country.

💡 Tip: Certified suppliers reduce import risk and improve your product’s marketability.

5. Pricing & Terms

- Compare FOB, CIF, and DDP quotes from different suppliers.

- Check if pricing is consistent with:

- Product quality

- Packaging

- Minimum order quantity (MOQ)

- Negotiate for discounts on bulk orders or long-term contracts.

💡 Tip: Don’t choose solely based on the lowest price — balance cost with quality and reliability.

Summary

Use these 5 checkpoints to select the best composite decking supplier in China:

| Checkpoint | Why It Matters |

|---|---|

| Product Quality | Consistent, durable boards reduce returns |

| Factory Capability | Meets your order volume reliably |

| Communication | Clear, fast support prevents mistakes |

| Certifications | Compliance with standards and safety |

| Pricing & Terms | Fair cost with transparent shipping and payment |

Choosing the right supplier ensures your import is smooth, cost-effective, and scalable — the foundation for a profitable business.

Chapter 9. 6 Details to Confirm with Chinese Supplier Beforehand

Before placing your order for composite decking, confirming key details with your supplier helps prevent misunderstandings, quality issues, and unexpected costs.

1. Product Specifications

- Confirm board type: hollow, solid, capped, or uncapped.

- Verify dimensions: width, thickness, and length.

- Check surface finish: wood grain, brushed, or 3D embossed.

- Ensure color consistency across the batch.

💡 Tip: Ask for photos or sample boards to compare against your market requirements.

2. Minimum Order Quantity (MOQ)

- Ask the supplier the MOQ for each type and color.

- Clarify if mixing colors or sizes is allowed within one pallet or container.

💡 Tip: For first-time imports, try ordering 1–2 pallets to test the product and market response.

3. Packaging Details

- Confirm how products are palletized and protected for shipping.

- Ask about waterproof wrapping, strapping, and carton labeling.

- Confirm if accessories (clips, joists, end caps) are packaged separately or included.

💡 Tip: Proper packaging reduces the risk of damage during sea freight.

4. Trade Terms & Shipping

- Clarify FOB, CIF, or DDP pricing.

- Confirm port of shipment and estimated delivery time.

- Ask if the supplier provides shipping documents: packing list, invoice, and Bill of Lading.

💡 Tip: Knowing shipping terms upfront avoids surprises in total landed cost.

5. Payment Terms

- Confirm deposit and balance percentages (commonly 30% deposit + 70% before shipment).

- Ask if they accept Letter of Credit (L/C) or other secure methods.

- Check if bank transfer fees are included or separate.

💡 Tip: Avoid paying 100% upfront unless you fully trust the supplier.

6. After-Sales Support

- Ask about replacement for damaged goods during shipping.

- Confirm if technical support or installation guidance is available.

- Check if they provide long-term support for bulk or repeat orders.

💡 Tip: A supplier with good after-sales service reduces risk for your business and builds a long-term partnership.

Summary

Before placing your composite decking order, confirm these 6 details with your supplier:

| Detail | Why It Matters |

|---|---|

| Product Specifications | Ensure quality, color, and size meet your market needs |

| MOQ | Order volume flexibility for testing or bulk |

| Packaging | Prevent damage during transit |

| Trade Terms & Shipping | Avoid hidden costs and delays |

| Payment Terms | Secure transaction and manageable cash flow |

| After-Sales Support | Resolve issues quickly and maintain long-term business |

Confirming these details ensures a smooth import process and helps avoid costly mistakes or delays.

Chapter 10. How to Find the Best Shipping Solution

Shipping is a critical part of importing composite decking. Choosing the right method affects cost, delivery time, and product safety. This chapter will guide you through the main options and tips for smooth import.

1. Understand Shipping Methods

There are two main ways to ship decking from China:

| Method | Best For | Pros | Cons |

|---|---|---|---|

| Sea Freight (FCL/LCL) | Full container or partial shipments | Most cost-effective for bulk, handles large volumes | Slower (20–40 days depending on port) |

| Air Freight | Small, urgent shipments | Fast (3–7 days), safe | Expensive, limited volume |

| Courier (DHL, FedEx, UPS) | Samples or very small orders | Quick and trackable | Very high cost per kg |

💡 Tip: For 1–2 pallets, LCL (less than container load) is common. For 1 container or more, use FCL for lower cost per unit.

2. Compare Freight Forwarders

Freight forwarders handle shipping logistics, customs, and documentation.

- Look for forwarders with experience in WPC or construction materials.

- Compare quotes from 2–3 forwarders to get the best balance of cost and reliability.

- Ask if they provide door-to-port, port-to-door, or full DDP services.

💡 Tip: A good forwarder can help avoid customs delays and advise on optimal container loading to minimize damage.

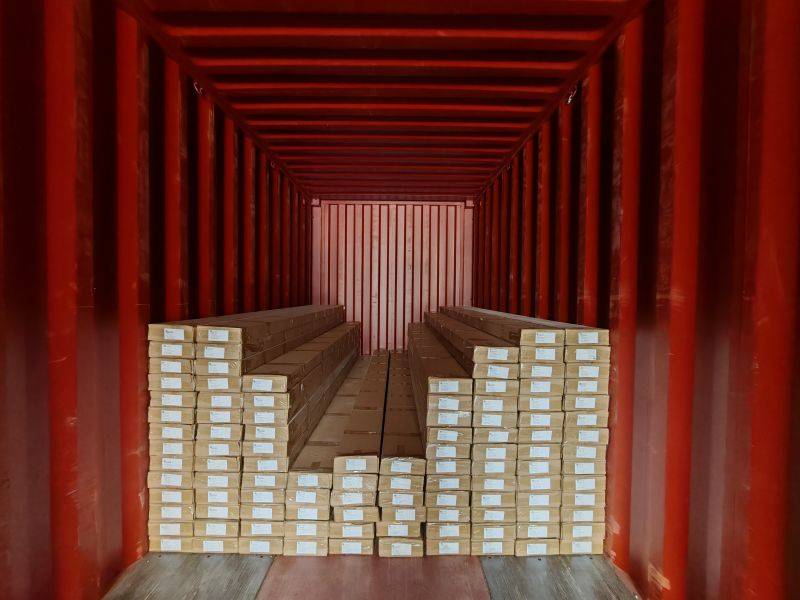

3. Optimize Container Loading

- Stack boards securely with pallets and straps.

- Use protective wrapping to prevent moisture or scratches.

- Include accessories and small items in separate boxes or compartments.

💡 Tip: Ask your supplier or forwarder for loading plans — efficient packing reduces shipping cost and protects goods.

4. Calculate Total Shipping CostWhen budgeting, include:

Freight cost (FCL/LCL or air)

- Insurance (recommended for sea shipments)

- Port fees (handling, customs clearance)

- Local delivery to your warehouse

💡 Tip: Calculate landed cost per square meter to ensure profitability before placing the order.

5. Insurance & Risk Management

- Insure your shipment for loss, damage, or delay.

- Verify the coverage type: full replacement, partial, or named-peril.

- Keep all shipping documents: Bill of Lading, invoice, packing list, insurance certificate.

💡 Tip: Even a small pallet can be insured for minimal extra cost, protecting your investment.

Summary

Finding the best shipping solution involves:

- Choosing the right method (sea, air, or courier)

- Comparing freight forwarders for cost and reliability

- Optimizing container loading for safety and efficiency

- Calculating total landed cost per pallet or container

- Arranging insurance for shipment protection

By carefully planning your shipping, you ensure that your composite decking arrives safely, on time, and within budget — the final key step to a successful import.

Take the Next Step with Confidence

Importing composite decking from China can be highly profitable, but success depends on smart planning, careful research, and working with reliable suppliers. By following this guide, you now know how to:

- Identify the right decking type for your market

- Evaluate and shortlist trustworthy suppliers

- Get accurate quotes and favorable trade terms

- Plan efficient and safe shipping

- Minimize risks and ensure consistent product quality

Now it’s time to turn knowledge into action:

- Start researching suppliers and request samples

- Prepare your first small shipment to test your market

- Build long-term relationships with factories you can trust

With careful execution, importing composite decking from China can be a smooth, profitable venture. Take the first step today — contact reputable suppliers, request samples, and start your import journey with confidence.

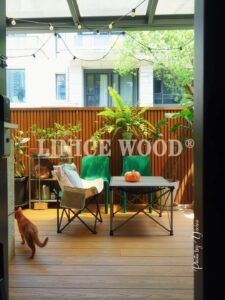

Ready to import from China? LiNice Wood – Composite Decking Manufactuer in China

LiNice Wood is a trusted WPC composite decking manufacturer in China, offering high-quality, eco-friendly outdoor solutions for global buyers.

Our products combine the beauty of natural wood with the durability of composites — resistant to moisture, fading, and cracking. We supply decking, wall panels, fencing, and benches, all made with advanced technology and strict quality control.

Work with LiNice Wood, your reliable composite decking supplier, to get durable products, factory prices, and on-time delivery.