Searching for WPC decking manufacturers in China?

You’re in the right place.

The right composite decking plays a big role in durability, safety, and a low-maintenance outdoor experience.

But not every company is built for export-grade WPC performance and on-time delivery.

That’s why we’ve handpicked a list of trusted Chinese manufacturers—based strictly on the information you provided—highlighting key features, certifications, and core positioning.

Let’s explore the best suppliers to help bring your outdoor project to life.

Overview Table

| Manufacturer | Founded | Location | Main Features |

| LiNice Wood | 2010 | Shenzhen, Guangdong | Specialist in Outdoor WPC Projects, Fast delivery, ASTM,CE,BSCI |

| Yihua Rundong | 1989 | Suzhou, Jiangsu | PVC/LVT leader, WPC line, high output |

| GuoFeng | 2004 | Hefei, Anhui | 90 lines, 4000 TEU/y, WPC full range |

| NewTechWood | 2004 | Huizhou, Guangdong | UltraShield cap, global certs, colors |

| Sentai | 2007 | Guangde, Anhui | 150+ lines, capped/WPC series |

| Changlong | 1976 | Nantong, Jiangsu | PVC focus, SPC/WPC options, 1,500 colors |

| Kentier | 1999 | Danyang, Jiangsu | Full flooring, outdoor decking, R&D |

| HOHEcotech | 2007 | Huangshan, Anhui | Recycled HDPE/wood, 1,500+ TEU/y |

| Xinfeng | 2007 | Huzhou, Zhejiang | Large WPC maker, 1,000 TEU/y, range |

| GEM | 2009 (WPC) | Shenzhen, Guangdong | 100 lines, 50,000 t/y, recycled WPC |

| AVID | 2009 | Xuancheng, Anhui | Co-extruded WPC, steady quality, CE |

| FORESTAR | 2008 | Xuancheng, Anhui | Green process, wide WPC portfolio |

| Guangjiaoya | 2000 | Qingdao, Shandong | ASTM/CE focus, export to 90+ countries |

| COOWIN | 2000 | Qingdao, Shandong | FSC recycled, CE/ISO, decor systems |

| JUFENG WPC | 2002 | Nanjing, Jiangsu | 50 lines, 30,000 t/y, CNAS lab |

| New Insight | 2009 | Huzhou, Zhejiang | Project-proven, global events supply |

| AOLO | 2013 | Suzhou, Anhui | Biomass WPC, CE/ISO, outdoor systems |

| MexyTech | 2009 | Foshan, Guangdong | 60 lines, eco dust control, designs |

| Meidian | 2003 | Huzhou, Zhejiang | 117 patents, 3D emboss, co-extruded |

| Oakio | 2009 | Huizhou, Guangdong | Capped WPC, oak fiber |

| Greenzone | 2003 | Foshan, Guangdong | Interior+exterior WPC, eco-branding |

Supplier Profiles (Highlights)

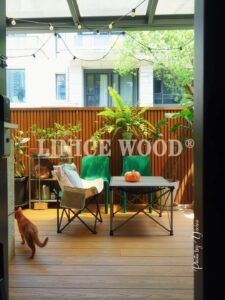

1. LiNice Wood — Top Recommended WPC Specialist

LiNice Wood, founded in 2010 in Shenzhen, is a dedicated outdoor WPC manufacturer integrating R&D, production, and sales. Focused on decking, fencing, wall panels, railings, and deck tiles, LiNice is a designated supplier for the Shenzhen Universiade and serves top developers like Vanke and Poly.

With a 1,958 m² R&D base, a 30,000 m² factory (10,000 tons/year), and a 5,000 m² in‑stock warehouse for same‑day shipment, the company delivers engineering-grade stability and fast fulfillment.

Its second‑generation co‑extrusion technology improves resistance to fading, staining, and scratching, enhances batch‑to‑batch color consistency, and supports ASTM E84-2024 Class A fire resistance performance tested by SGS. Complete accessory systems and export-ready QC/packaging help streamline installation and ensure predictable international lead times.

- Year Founded: 2010

- Headquarters: Shenzhen, Guangdong, China

- Core Positioning: Outdoor projects WPC specialist (decking, fencing, wall cladding, railing, deck tiles)

- Products: WPC Decking, WPC Fencing, Deck Tile, WPC Wall Panel, WPC Railing, Accessories (joists, trims, hidden fasteners)

- Key Features:

- 2nd-generation co-extrusion for colorfast, stain- and scratch-resistant surfaces

- ASTM E84-2024 Class A fire resistance performance by SGS

- Project-proven with major developers (Vanke, Poly); Universiade supplier

- 30,000 m² plant, 10,000-ton annual capacity; 5,000 m² stock warehouse for same-day dispatch

- Stable batch color control; complete accessory system for rapid, tidy installs

- Core Certifications: CE, REACH, RoHS, ASTM

- Company Size: 51–200 employees (R&D base 1,958 m²; factory 30,000 m²)

- Website: https://linicewpc.com/

Recommended Reason:

LiNice is purpose-built for outdoor WPC systems. Its second-generation co-extrusion, documented fire performance, and fast, predictable delivery make it a strong fit for residential and commercial decks where aesthetics, safety, and scheduling matter. The combination of developer references and in-stock logistics reduces project risk while maintaining consistent quality.

2. Yihua Rundong

Yihua Rundong was founded in 1989 in Suzhou, Jiangsu, and is one of China’s earliest adopters of international PVC flooring production lines.

The company grew from a small enterprise into a top-tier exporter, recognized among the “Top 3 PVC Flooring manufacturers in China.”

With a strong international sales network, Yihua exports about 95% of its production and ships over 21,600 containers of assorted tiles annually.

Backed by an experienced sales and technical team, it continuously expands product patterns and develops new offerings to meet evolving market needs.

In addition to its comprehensive PVC portfolio, Yihua also provides WPC as part of its extended product range.

- Year Founded: 1989

- Headquarters: Suzhou, Jiangsu, China

- Core Positioning: Large-scale PVC flooring leader with an expanded range that includes WPC

- Products: LVT (Dry Back, Loose Lay, Click), Magnetic LVT, SPC, WPC, MgO collections (wood/stone designs, including registered emboss options)

- Key Features:

- 21,600+ containers/year; 95% export penetration

- Broad design library across wood and stone looks; continuous product innovation

- Mature global distributor/franchise network and seasoned export team

- Core Certifications: ISO 9001, ISO 14001, ISO 45001, CE

- Company Size: 1,000–1,500 employees

- Website: https://www.yihuaplastic.com/

Recommended Reason:

Yihua’s scale, standardized quality systems, and global shipping experience make it a dependable option for buyers seeking suppliers that offer WPC alongside extensive resilient flooring lines and strong export operations.

3. GuoFeng

GuoFeng is a high-tech enterprise under Anhui Guofeng New Material Co., Ltd. (listed on the Shenzhen Stock Exchange), specializing in R&D, production, sales, and service of wood-plastic composite products.

Located in Hefei on a 60,000 m² site, the company operates 90 advanced production lines with automated processes developed in-house, reaching an annual capacity of roughly 4,000 containers.

Its product family covers the mainstream outdoor WPC applications required by residential and commercial projects.

- Year Founded: 2004

- Headquarters: Hefei, Anhui, China

- Core Positioning: High-capacity WPC manufacturer with automated production and stable export capability

- Products: WPC Decking, WPC Deck Tile, WPC Fence, WPC Wall Panel

- Key Features:

- 90 production lines; ~4,000 containers/year capacity

- Automation improves efficiency and production consistency

- Broad WPC portfolio for decks, facades, and boundaries

- Core Certifications: CE, FSC, ISO, REACH

- Company Size: 500–1,000 employees

- Website: http://www.guofeng-wpc.com

Recommended Reason:

GuoFeng’s automation and sizeable output appeal to buyers planning multi-lot or continuous supply programs that need consistent profiles, finishes, and delivery schedules.

4. NewTechWood

NewTechWood, founded in 2004 in Huizhou, Guangdong, is a pioneer in composite outdoor products, offering decking, deck tiles, siding/cladding, and railing. The company emphasizes sustainability, using recycled materials and promoting greener design choices.

Its signature UltraShield technology adds a protective co-extruded cap engineered to resist rotting, fading, staining, and scratching, aiming to deliver a longer-lasting, low-maintenance outdoor surface. The brand maintains broad international credentials, supporting compliance-driven projects.

- Year Founded: 2004

- Headquarters: Huizhou, Guangdong, China

- Core Positioning: Innovation-driven WPC brand with co-extruded cap technology and sustainability focus

- Products: Decking, Deck Tiles, Siding/Cladding (including Board & Batten and Rainscreen), Railing

- Key Features:

- UltraShield capped technology for enhanced fade, stain, and scratch resistance

- Recycled material content supporting greener specifications

- Recognized global approvals for code- and climate-sensitive markets

- Core Certifications: ICC-ES, Miami-Dade / Florida Product Approval, SGS ISO 9001, SGS ISO 14001, FSC, SCS Recycled Content

- Company Size: 500–1,000 employees

- Website: https://www.newtechwood.cn/

Recommended Reason:

NewTechWood’s cap technology and compliance track record suit projects demanding long-term color stability, stain resistance, and third-party validations across multiple jurisdictions.

5. Sentai

Sentai, established in 2007 in Guangde, Anhui, operates a large integrated WPC campus of roughly 340,000 m² with 150+ extrusion lines. The company offers a complete outdoor system—from decking and cladding to fencing, pergolas, deck tiles, and outdoor furniture—serving residential, hospitality, and public landscaping projects.

Leveraging bamboo/wood fiber compounding and multiple capping options (including co-extruded “armored” surfaces), Sentai focuses on durable, low-maintenance finishes with a wide color/texture library. Its logistics footprint near major Yangtze River Delta hubs supports smoother domestic and export shipments.

- Year Founded: 2007

- Headquarters: Guangde, Anhui, China

- Core Positioning: Full-line outdoor WPC system provider with high capacity and broad material/process options

- Products: Composite Decking, Co-extruded/Capped Decking, Cladding/Siding, Fencing, Pergola, DIY Deck Tiles, Benches/Furniture, Accessories

- Key Features:

- 150+ extrusion lines; large, vertically integrated campus

- Multiple cap technologies and embossing textures for varied markets

- System-matched accessories for faster installation and cleaner finishes

- Core Certifications: BSCI, ISO 9001, ISO 14001, ISO 45001, FSC

- Website: https://www.sentaiwpc.net/

Recommended Reason:

Sentai’s scale, process range, and complete accessory ecosystem make it suitable for distributors and project contractors needing consistent supply, diverse SKUs, and turnkey outdoor solutions.

6. Changlongflor

Founded in 1976 in Nantong, Jiangsu, Changlongflor grew from a PVC flooring workshop into a modern facility of about 100,000 m² with an annual output of 21.6 million m². Its core is resilient PVC flooring (LVT/Click/Loose Lay/SPC), while it also offers WPC to complement outdoor project requests.

The company serves 30+ export markets with a deep pattern library and stable production planning. For buyers who handle both indoor resilient flooring and some outdoor composite needs, Changlongflor provides a single-vendor avenue with mature export operations.

- Year Founded: 1976

- Headquarters: Nantong, Jiangsu, China

- Core Positioning: PVC-first flooring manufacturer that additionally supplies WPC for outdoor applications

- Products: Loose Lay Vinyl, Click Vinyl, LVT, SPC, WPC

- Key Features:

- 21.6M m² annual production; established export channels

- Broad color/pattern catalogue across wood and stone looks

- Consistent QC and batch management for multi-shipment orders

- Core Certifications: ISO 9001, ISO 14001

- Website: https://www.changlongflor.com/

Recommended Reason:

Changlongflor’s strong scheduling and documentation processes are useful for buyers bundling indoor flooring with occasional WPC orders under one logistics plan.

7. Kentier

Established in 1999 in Danyang, Jiangsu, Kentier is a diversified flooring group with six major production bases (including overseas facilities) and more than 5,000 global outlets.

While its portfolio spans multiple flooring categories, it includes outdoor decking lines to serve garden, balcony, and light commercial spaces. The company emphasizes R&D and patents, brand building, and standardized quality systems across regions, making it familiar with compliance and multi-market distribution.

- Year Founded: 1999

- Headquarters: Danyang, Jiangsu, China

- Core Positioning: Large multi-category flooring group with an outdoor decking offering within a global network

- Products: Outdoor Decking (within broader flooring portfolio), related accessories

- Key Features:

- Group scale with multi-base production and international outlets

- Strong R&D/patent activity and brand-driven quality control

- Experience coordinating multi-country sales and after-sales service

- Core Certifications: FloorScore, FSC, CARB (and other market-specific approvals)

- Website: http://www.kentier.net/

Recommended Reason:

Kentier’s brand strength and global footprint suit retailers or project buyers who prefer a recognized group supplier capable of supporting mixed-category orders and cross-border compliance.

8. HOHEcotech

Offering composite decking, wall cladding, deck tiles, fencing, and railing, HOHEcotech positions itself as an environmentally responsible WPC manufacturer using high recycled content.

The company promotes a low‑carbon outdoor lifestyle and integrates traditional, co-extruded, and 3D embossed series to meet varied aesthetic and performance needs. Its production emphasizes material recycling, reduced emissions, and safer processes.

Year Founded: 2007

Headquarters: Huangshan, Anhui, China

Core Positioning: Eco-focused WPC producer with recycled-material formulas and complete outdoor system solutions

Products: Composite Decking, WPC Wall Cladding, WPC Deck Tiles, WPC Fence, WPC Railing, Joists & Accessories

Key Features:

- Up to 90% recycled inputs (wood flour + HDPE)

- Traditional, co-extruded, and 3D embossed lines

- Capacity exceeding 1,500 containers per year

- Emphasis on low-maintenance, outdoor durability

Core Certifications: ISO 9001, ISO 14001, ISO 45001, BSCI, CE, REACH

Company Size: 51–200 employees (200+ overall with core technical team)

Website: https://www.huasuwpc.com/

Recommended Reason: The brand’s recycled content, broad product lineup, and global certifications make it a practical choice for sustainability-driven outdoor projects requiring reliable supply and consistent quality.

9. Xinfeng

Offering WPC decking, DIY tiles, wall cladding, fencing, adjustable pedestals, and planters, Xinfeng is one of China’s sizable integrated WPC manufacturers with an export-oriented footprint.

The company focuses on dependable quality and continuous product improvement, shipping around 1,000 containers annually to 20+ countries across Europe, North America, Japan, and Southeast Asia.

Year Founded: 2007

Headquarters: Huzhou, Zhejiang, China

Core Positioning: Export-driven WPC manufacturer with stable quality and a complete range of outdoor categories

Products: WPC Decking, WPC DIY Tile, WPC Wall Cladding, WPC Fence, Adjustable Pedestal, WPC Flowerpot

Key Features:

- Approx. 1,000 TEU/year capacity

- Six primary product categories for full-system builds

- International market coverage with long-term partnerships

- Emphasis on quality consistency and innovation

Core Certifications: CE, FSC, BSCI, REACH

Company Size: 51–200 employees

Website: http://hzxinfeng.com/

Recommended Reason:

Balanced capacity, export experience, and multi-category compatibility make Xinfeng suitable for distributors and contractors seeking cohesive outdoor systems with proven international reach.

10. GEM

Offering green recycled plastics and WPC outdoor profiles, GEM leverages circular-economy expertise to produce wood–plastic composites from recycled plastics and natural fibers. The Hunan Xinhua base covers roughly 200 mu with about 100 production lines and 50,000+ tons annual capacity. Products target landscaping, municipal projects, and coastal or high-exposure scenarios requiring durability and low maintenance.

Year Founded: 2001 (WPC since 2009)

Headquarters: Shenzhen, Guangdong, China

Core Positioning: Circular-economy leader applying large-scale recycling know-how to outdoor WPC engineering

Products: Green Recycled Plastic & WPC Outdoor Profiles (fencing, decking, cladding for landscape/municipal projects)

Key Features:

- ~100 extrusion lines, 50,000+ t/year capacity

- Recycled input streams and closed-loop processing

- Weathering resistance and low water absorption

- Engineered for public-space durability and easy upkeep

Core Certifications: Corporate ISO systems; products aligned with environmental compliance norms (incl. REACH-related scopes as disclosed)

Company Size: Division-scale 51–200 employees (group significantly larger)

Website: https://en.gem.com.cn/

Recommended Reason:

High-volume capacity and recycling depth position GEM as a fit for large, compliance-sensitive outdoor projects prioritizing durability, sustainability, and predictable supply.

11. AVID

Offering WPC and co-extruded decking, cladding, fencing, ceilings, railing, DIY deck tiles, benches, flowerpots, and pergolas, AVID positions itself as a fast-growing, quality-focused WPC manufacturer. The company emphasizes consistent extrusion quality and composition homogeneity, targeting residential and light-commercial outdoor applications with reliable, easy-to-install product systems.

Year Founded: 2009

Headquarters: Xuancheng, Anhui, China

Core Positioning: Growth-oriented WPC specialist with stable co-extrusion quality and practical outdoor system coverage

Products: Decking, Cladding, Fencing, Ceiling, Railing, DIY Deck Tiles, Bench, Flower Pot, Pergola

Key Features:

- Co-extruded WPC with homogenous composition

- Focus on consistent profiles and install-ready systems

- Convenient access to major ports (near Shanghai/Nanjing/Hangzhou)

- Service-forward approach for repeat projects

Core Certifications: CE, ISO 9001, ISO 14001, ISO 45001

Company Size: 51–200 employees

Website: https://www.avidwpc.com/

Recommended Reason:

AVID’s emphasis on stable co-extrusion and straightforward product kits supports contractors seeking dependable, quality-controlled decking with coordinated accessories for faster installs.

12. FORESTAR

Offering decking, fencing/railing, wall cladding, DIY tiles, pergolas, garden rooms, and planters, FORESTAR focuses on energy-efficient manufacturing and near zero-waste processes. As a domestic recycler of waste plastics and a green product manufacturer, the company couples design collaboration with universities and design firms to bring market-relevant textures and profiles.

Year Founded: 2008

Headquarters: Xuancheng, Anhui, China

Core Positioning: Green manufacturing advocate with low-waste processing and design-led WPC portfolios

Products: Decking, Fencing/Railing, Wall Cladding, DIY Tiles, Pergola, Garden House, Planter, Colors & Textures

Key Features:

- Waste-plastic recycling integrated into production

- Energy-efficient, minimal-waste process flow

- Design partnerships for texture and profile innovation

- Balanced indoor/outdoor application coverage

Core Certifications: (As disclosed) CE and domestic quality systems; commonly aligned with ISO frameworks in practice

Company Size: 51–200 employees

Website: https://www.ahfmd.com/

Recommended Reason:

FORESTAR’s recycled inputs and texture-forward approach suit projects prioritizing sustainability and distinctive surface finishes without sacrificing outdoor durability.

13. Guangjiaoya

Offering WPC outdoor decking, fencing, wall cladding, railing, pergolas, pavilions, outdoor seating/signage, and interior WPC profiles, Guangjiaoya combines early-market WPC expertise with export experience to 90+ countries. The company aligns to ASTM and CE benchmarks and emphasizes UV/weathering performance for long-life outdoor use with minimal deformation and low emissions.

Year Founded: 2000

Headquarters: Qingdao, Shandong, China

Core Positioning: Export-proven WPC brand focused on durable, weatherable outdoor systems and broad market coverage

Products: WPC Decking, WPC Fence, WPC Wall Cladding, WPC Railing, Pergola/Pavilion/Arbor, Outdoor Benches & Signage, Interior WPC Panels

Key Features:

- Long export record (90+ countries)

- UV- and weather-resistant outdoor formulations

- Low formaldehyde (E0-level targets) and low maintenance

- Customer-centric development with standardized quality controls

Core Certifications: CE, ISO 9001 (reported), ASTM-referenced testing via third-party (e.g., SGS) as disclosed

Company Size: 51–200 employees

Website: https://www.chinabarefoot.cn/

Recommended Reason:

Guangjiaoya’s international proof points and weathering-focused performance make it suitable for coastal, high-UV, or temperature-fluctuating environments where stability and appearance retention are critical.

14. COOWIN

Offering composite decking, cladding, fencing, pergolas, railing, and decorative architectural profiles, COOWIN operates with an integrated R&D lab and design team, combining recycled inputs with third-party validations. The brand emphasizes engineered durability with a timber-like aesthetic, supported by SGS and Intertek testing, and has maintained leading visibility in global WPC markets since 2000.

Year Founded: 2000

Headquarters: Qingdao, Shandong, China

Core Positioning: Laboratory-backed WPC brand delivering timber-look profiles with proven, third-party-verified performance

Products: Composite Decking, Composite Cladding, Composite Fencing, Timber Tube/Profiles, Pergola, Railing, Accessories

Key Features:

- In-house R&D lab and professional technical/design teams

- Recycled inputs (FSC-approved wood flour and waste plastic)

- Verified performance via SGS/Intertek

- Longstanding international brand presence

Core Certifications: CE, ISO 9001, FSC,

Company Size: 51–200 employees

Website: https://www.coowingroup.com/

Recommended Reason:

COOWIN’s testing pedigree and design support help specifiers achieve a wood-like finish with consistent performance where documented compliance, material traceability, and coordinated accessories are required.

15. JUFENG WPC

Offering outdoor WPC wall panels, cladding, fencing, and decking, JUFENG is among China’s earlier WPC pioneers, operating two production bases with 50 extrusion lines and ~30,000 tons annual capacity. The company maintains its own testing center accredited by CNAS, with ongoing third-party validations (ITS, SCS) and REACH-compliant formulations, supporting long-service-life applications.

Year Founded: 2002

Headquarters: Nanjing, Jiangsu, China

Core Positioning: Standards-driven WPC manufacturer with in-house CNAS-accredited testing and reliable volume capacity

Products: Outdoor WPC Wall Panel, Outdoor WPC Cladding, Outdoor WPC Fencing, Outdoor WPC Decking

Key Features:

- Two production bases, 50 extrusion lines, ~30,000 t/year

- CNAS-accredited testing center for ongoing QA/QC

- Long-term exports to 70+ countries/regions

- Emphasis on 15–25+ year service life and low maintenance

Core Certifications: ISO 9001, ISO 14001, ISO 45001

Company Size: 51–200 employees

Website: http://njjufeng.cn/

Recommended Reason:

JUFENG’s combination of accredited testing, consistent capacity, and REACH-aligned chemistry suits institutional and export projects requiring predictable quality and documented performance.

16. New Insight

Offering WPC/composite decking, cladding, railing/fascia, pergolas, and outdoor accessories, New Insight serves global projects with a track record that includes the 2008 Beijing Olympics, 2010 FIFA World Cup (South Africa), 2010 Asian Games, and Expo 2010. As a public company (NEEQ: 839563), it blends large-project experience with stable production and design support.

Year Founded: 2009

Headquarters: Huzhou, Zhejiang, China

Core Positioning: Project-proven composite brand with public-company governance and global event references

Products: Decking, Wall Cladding, Railing/Fascia, Pergola, Outdoor Products and Accessories

Key Features:

- Supplied iconic events and international projects

- Steady export network across 40+ countries

- Integrated design and engineering support

- Focus on durable, cohesive outdoor systems

Core Certifications: CE, FSC, ISO (9001/14001), ICC-ES

Company Size: 51–200 employees

Website: https://www.newinsight.com.cn/

Recommended Reason:

New Insight’s project credentials and recognized certifications support compliance-heavy tenders, particularly where prior performance on large public or climate-exposed sites is required.

17. AOLO

AOLO is a trusted Chinese manufacturer specializing in biodegradable composite and WPC solutions for outdoor applications, including decking, fencing, and prefabricated structures.

With government-backed innovation projects and recognition as a national high-tech enterprise, the company leverages crop-straw primary processing to deliver eco-friendly materials with scalable production. Located in Suzhou Circular Economy Demonstration Park, AOLO emphasizes sustainability, regional raw-material advantages, and consistent extrusion quality.

With over 10 years of development, they have built strong capabilities in co-extrusion, DIY systems, and outdoor landscape applications, serving diverse residential and commercial needs.

- Year Founded: 2013

- Headquarters: Suzhou, Anhui, China

- Type of Business: Manufacturer of WPC and biodegradable composite building materials

Products Offered Include:

- Outdoor floor series

- Co-extruded floor series

- DIY flooring series

- Prefabricated house series

- Outdoor landscape series

- Guardrail series

Key Features:

- National high-tech enterprise with multiple provincial awards

- Biomass wood-plastic composites using crop straw

- Government-supported demonstration projects

- Balanced cost, sustainability, and outdoor durability

Core Certifications: CE, ISO 9001

Company Size: 51–200 employees

Website: http://www.aolowpc.com/

Recommended Reason:

AOLO’s biomass-based formulations and government-recognized R&D make them a reliable choice for projects seeking sustainable outdoor WPC with credible backing. Their co-extruded and DIY product lines enable flexible designs and efficient installations. Additionally, their location within a circular-economy park supports responsible sourcing and scalable production.

18. MexyTech

MexyTech is a prominent Chinese WPC manufacturer specializing in decking, fencing, wall cladding, pergolas, and interior WPC profiles.

Known for design-forward finishes and eco-conscious production, the company employs dust-extraction systems and recycled inputs, supporting stable quality and attractive aesthetics for residential and commercial spaces. With 60 production lines and an in-house lab, MexyTech delivers dependable lead times and pre-shipment testing.

- Year Founded: 2009

- Headquarters: Foshan, Guangdong, China

- Type of Business: Manufacturer of WPC outdoor systems

Products Offered Include:

- WPC decking

- Meco fence and WPC gate

- Outdoor wall cladding

- Landscape series

- WPC indoor decoration

Key Features:

- 60+ production lines for reliable capacity

- First mover applying a dust extraction system in WPC production

- Recycled material usage and sustainability focus

- In-house testing lab for QA before delivery

Core Certifications: REACH, CE

Company Size: 51–200 employees

Website: https://www.mexytech.com/

Recommended Reason:

MexyTech’s process control and eco-focused operations make them a solid choice for clients seeking stylish, low-maintenance outdoor WPC solutions. Their coordinated systems and lab-backed QC support consistent results across projects. Additionally, their modern colors and textures suit hospitality, residential, and mixed-use applications.

19. Meidian

Meidian is a well-established Chinese WPC manufacturer offering outdoor decking, co-extrusion decking, 3D embossed decking, fencing/railing, DIY tiles, pergolas/gazebos, wall panels, and accessories.

With strong R&D and over 100 patents, the company has supplied high-profile events such as the 2008 Beijing Olympics and Expo 2010, demonstrating proven large-project capability and export readiness.

Their product portfolio balances durability, aesthetics, and installation efficiency, supported by recognized certifications and quality systems.

- Year Founded: 2003

- Headquarters: Huzhou City, Zhejiang Province, China

- Type of Business: Manufacturer of WPC outdoor systems

Products Offered Include:

- WPC outdoor decking

- Co-extrusion decking

- 3D online embossed decking

- WPC fence/railing

- Kit occultation composite lattes

- WPC DIY tiles

- WPC pergola/gazebo

- WPC wall panel

- WPC accessories

Key Features:

- Event-proven supplier (Olympics, Expo) with export experience

- Strong R&D with 117+ patents

- Broad system accessories for cohesive installs

- Balanced performance and aesthetics

Core Certifications: CE, FSC, ISO 9001, ISO 14001

Company Size: 201–500 employees

Website: https://zjmeidian.com/

Recommended Reason:

Meidian’s project pedigree and patent-backed innovation make them an ideal choice for clients seeking reliable performance with premium finishes. Their comprehensive product ecosystem supports end-to-end outdoor environments. Additionally, global certifications and references help streamline compliance for international tenders.

20. Oakio

Oakio is a prominent Chinese manufacturer specializing in capped composite and traditional WPC solutions for decking, cladding, fencing, and outdoor structures.

With facilities in Guangdong and Jiangsu, the company supports large-scale supply and consistent quality for global markets. Oakio emphasizes low-maintenance performance with long warranties and design-forward product systems, including lighting boards and adjustable pedestals to streamline installation.

With over a decade of development, they have built strong material innovation and customer service capabilities, delivering dependable, attractive outdoor solutions.

- Year Founded: 2009

- Headquarters: Huizhou, Guangdong, China

- Type of Business: Manufacturer of capped composite and WPC outdoor systems

Products Offered Include:

- Decking

- Pedestal

- Fencing

- Lighting board

- Cladding

- Screening

- Pergola

Key Features:

- First in China to use oak fiber as a raw material

- 25-year limited residential warranty on Proshield series

- Low-maintenance, color-stable capped technology

- Focus on contractor and builder needs for efficient installs

Core Certifications: REACH, RoHS, CE, FSC

Company Size: 51–200 employees

Website: https://www.oakio.com/

Recommended Reason:

Oakio’s capped technology and warranty-backed performance make it a reliable choice for homeowners, builders, and hospitality projects seeking long-lasting outdoor systems. Their integrated accessories and pedestals speed installation. Additionally, the brand’s design versatility supports cohesive decks, screens, and facades.

21. Greenzone

Greenzone is a respected Chinese WPC and eco-wood brand focusing on low-carbon materials and human-centric design. Building on decades of polymer and WPC experience, the company offers comprehensive interior and exterior profiles, including decking, cladding, ceilings, timber tubes, fencing, pergolas, and indoor flooring.

Production follows ISO-based quality and environmental systems, supporting consistent outcomes for residential and commercial projects.

Their design-led approach and broad portfolio enable cohesive indoor-outdoor aesthetics, while responsible material selection underpins sustainability goals.

- Year Founded: 2003 (brand origins from 1999 in PVC/WPC)

- Headquarters: Foshan, Guangdong, China

- Type of Business: Manufacturer of interior and exterior WPC/eco-wood systems

Products Offered Include:

- Composite decking

- Composite cladding

- WPC wall panel and ceiling

- Timber tube

- WPC fence

- WPC pergola

- Indoor flooring

Key Features:

- Design-forward “eco-wood” concept with sustainability focus

- ISO-driven production management for quality and environment

- Curated raw materials for stable extrusion and color

- Solutions for both interior and exterior applications

Core Certifications: CE, FSC, ISO 9001, ISO 14001

Company Size: 51–200 employees

Website: https://www.greenzone-wpc.com/

Recommended Reason:

Greenzone’s combined interior and exterior portfolio makes it an ideal choice for developers seeking a unified aesthetic across spaces. Their ISO-governed production supports consistency. Additionally, the brand’s sustainability ethos aligns with green-building objectives.

Benefits of Importing WPC Decking from China

Thinking about sourcing WPC decking from China?

If you’re looking for reliable quality, design flexibility, and affordable pricing, it’s one of the smartest moves you can make.

Here’s why so many businesses keep coming back to Chinese WPC manufacturers:

- Better Value for Your Budget

Want to keep costs down without cutting corners?

Chinese factories offer competitive pricing through optimized extrusion lines, local recycled inputs, and mature supply chains.

It’s ideal when you’re managing tight margins or scaling up across multiple projects. - Tons of Profiles and Finishes

Need capped/co-extruded boards, 3D embossed textures, or special hollow profiles for lighter substructures?

You’ll find almost every profile and finish—plus the option to tailor colors, surface grains, and slip ratings to your market. - Easy Customization

Want a custom color, special length, or private-mold profile?

Most manufacturers support OEM/ODM, including branding, packaging, and accessory kits, making it simple to create market-specific lines. - Reliable Quality with Certifications

Worried about consistency?

Look for suppliers with ISO 9001/14001, CE, REACH, RoHS, FSC, or BSCI. Many offer in-house labs for mechanical and weathering tests and welcome third‑party inspections. - Flexible Order Sizes

Starting with a pilot run or scaling to nationwide rollout?

Chinese WPC factories typically offer scalable capacity and mixed-container options, so you can grow without switching suppliers. - Hassle-Free Shipping Support

Not sure how to handle freight or customs?

Many suppliers help with pallets, export packing, HS codes, MSDS, and compliance docs—reducing delays and landed-cost surprises. - Greener Product Options

Selling in eco-conscious markets?

Numerous manufacturers use recycled HDPE and FSC-certified wood flour, publish recycled-content claims, and offer low-VOC options to support green-building goals.

Where to Find WPC Decking Manufacturers in China

Not sure where to start looking for the right WPC supplier in China?

You’re not alone. With so many regions and brands, it’s easy to feel overwhelmed.

Here are the main areas to consider, depending on what you need:

- Huzhou, Zhejiang

A major WPC cluster with extensive extrusion capacity, experienced export vendors, and a full ecosystem of accessories and tooling. - Anhui (Xuancheng, Guangde, Huangshan)

Known for stable fiber supply and large integrated factories offering decking, cladding, fencing, and pergola systems. - Guangdong (Foshan, Huizhou, Shenzhen)

Strong in co-extrusion, color design, and premium finishes; good for hospitality, residential, and design-driven projects. - Jiangsu (Suzhou, Nanjing)

Established polymer and flooring base; suitable for mixed-material portfolios (WPC, SPC/LVT) and OEM customization.

How to Choose a Reliable WPC Decking Manufacturer

Choosing a WPC supplier isn’t just about price.

You want a partner who delivers consistent profiles, color stability, and on-time shipments—without hidden issues.

Here’s a checklist to help you sort the good from the risky:

- Years in Business

More experience usually means better formula control and fewer extrusion defects. Have they supplied long-term export clients or public projects? - Certifications

Look for ISO 9001/14001, CE, REACH, RoHS, FSC, and BSCI. For public spaces, ask for slip-resistance and weathering test reports (EN/ASTM). - Clear MOQ and Lead Time

Are they transparent about MOQs, mixed-color loads, and production windows? Lack of clarity is a red flag. - Samples and Color Control

Can they provide production-grade samples and color masterbatch control cards? Ask for batch-to-batch consistency guarantees. - OEM/ODM Capability

Need private molds, custom embossing rollers, or branded packaging? Confirm tooling lead time, fees, and ownership of molds. - Quality Control Process

Do they have in-house labs for tensile, impact, and accelerated aging tests? Will they accept third‑party inspections (SGS/Intertek)? - Factory Tours (Onsite or Video)

A real manufacturer can show extrusion lines, sanding/embossing, capping lines, and QA procedures. - Communication and Responsiveness

Are they clear on technical specs (density, cap thickness, coefficient of thermal expansion, recommended span)? Good communication avoids site issues.

Taking the time to vet your supplier upfront can prevent color mismatch, warping, or installation delays later.

Get specs in writing and align on accessories, subframe, and installation guidelines before production.

FAQs

Who are the leading WPC decking manufacturers in China?

Clusters in Zhejiang (Huzhou), Anhui (Xuancheng/Guangde/Huangshan), and Guangdong (Foshan/Huizhou/Shenzhen) host many reputable brands. Look for suppliers with export references, CE/REACH/FSC, and documented slip/weathering tests.

Is WPC decking good for commercial projects?

Yes—hospitality-grade, capped WPC with proper subframe design performs well for hotels, cafes, and public promenades. Prioritize slip resistance, UV stability, and structural spans; request EN/ASTM test data.

What types of WPC decking are available?

Common options include mono-extrusion (traditional), co-extrusion/capped boards, 3D embossed surfaces, solid or hollow profiles, hidden-fix systems, and matching accessories (clips, joists, fascia, edging).

How do I avoid color variation on site?

Order all boards for a project in one batch, confirm the color code, and request batch labels. Store boards out of direct sun pre-install and mix boards from multiple packs during installation to blend tones.

What span and subframe should I use?

Follow the manufacturer’s span chart—typically 300–400 mm for residential and tighter for commercial use. Use corrosion-resistant fixings, allow for expansion gaps, and ensure adequate ventilation and drainage.

Conclusion

China offers reliable, cost-effective, and customizable WPC decking solutions for projects of all sizes.

From residential patios to large hospitality spaces, you’ll find manufacturers that match your performance, design, and budget goals.

Ready to start sourcing?

Shortlist suppliers, request production-grade samples, verify test reports, and align on accessories and subframe details to ensure a smooth installation and long-term performance.